Add to Cart

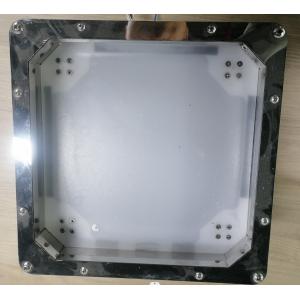

Flexible vibration feeder is a new type of vibration, in the square tray shape,which make it diversified and easy to operate, and make up the disadvantages of traditional vibration products dullness and frequent replacement cumber, It can screen most of small components in factories automatically. It is also known as a flexible feeding plate, flexible vibrating plate,flexible feeder etc.

With the rapid development of enterprises and the product generation upgrading, it is common to see shifting different materials in production. Traditional vibration feeder are mainly designed and manufactured for single produt independently, recently there are no longer suitable for the new requirements of part updating.

At present, the flexible vibration feeder equipped with machine vision, effectively solves the headaches of feeding problem of different products like thin sheet, easily scratched and damaged, and irregular workpiece, reduces manual labor intensity, and also avoids secondary damage to the product caused by manual labor. Intelligent processing and assembly help customers build intelligent factories.

| Model | CLX-FVF-300 |

| Product Dimension | 300*300*170mm |

| Plate size | 300*300*50mm |

| Suitable products | Strip shape(L≦70mm),thin clip(Ø5-45mm) |

| Materials | Stainless steel + hard plastic |

| Vibration | Vibration adjustable,mainly at ±5mm |

| Max product weight | 1.5KG |

| Working type | Step motor drive, 4pcs |

| POE | DC 24V/5A |

| Led light | Led light optional at Red/Blue/White, Background light with strip or plate light. |

| Manual Control | 4pcs manual button, for manual test |

| HMI | Same Monitor with machine vision |

| Moving mode | 15 kinds |

| Communication | Modbus,can be customized as buyer's request |

| Connection | RS485 |

small vibration parrts

Customized robot is working on garapping the com[onents